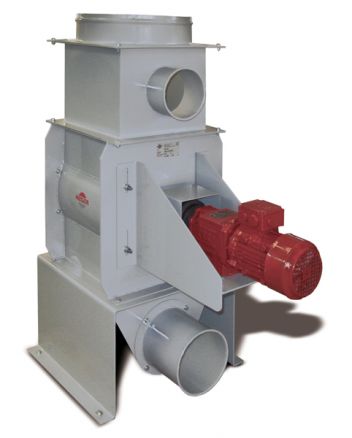

The Heger PowerMix line – The perfect solution for mixing and dosing different granulates

The Heger PneuMix line of mixing and dosing systems is used on moulding machines for homogeneous mixing of EPS or fresh EPP material with processed regranulate. The use of processed EPS or EPP granulate in manufacturing moulding reduces the use of expensive new material. Up to 50 percent processed granulate can be added.

The Heger PowerMix line of mixing and dosing systems allows homogeneous mixing of fresh EPS granulate with processed EPS regranulate. Thanks to its high mixing and dosing capacities, PowerMix is particularly suitable for EPS block foamers. PowerMix is particularly efficient with a mixing material throughput of 35 – 200 cubic metres per hour.

Technical features

- Optimal efficiency thanks to a performance-oriented machine concept

- High level of flexibility due to freely definable mixing ratios of 2 - 98 percent

- High degree of operational safety due to filling level monitoring of the component silos and buffer silos using rotating paddle switches

- Customisable thanks to the modular overall construction concept

- Fully automatic operational mode thanks to state-of-the-art SPS control from Siemens

- Highly efficient thanks to low operating and maintenance costs

- Simple commissioning thanks to delivery ready to be plugged in

- CE marking

The two dosing feeders are installed directly below the silo outfeeds of the individual mixing components.